Relying on the company's core We can meet the same conductivity needs with thinner Cu layer improving the mass energy density.

The innovative one-step magnetron sputtering method is used to improve safety while achieving thinning of the polymer base film, further increasing the volume energy density.

Refined magnetron sputtering technology realizes multi-scenario application expansion,providing solutions for different application scenarios such as high specific energy, long cycle, and zero attenuation.

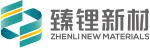

“Cicada's Wings” Series

Composite Copper Foil

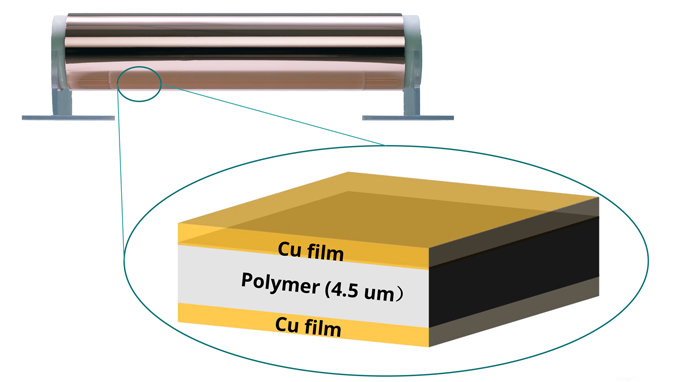

"Scale Armor" Series

Composite Aluminum Foil

"Visionary" Series

Key Materials For New Energy

“Cicada's Wings” Series

* Compared with traditional 6μm copper foil

Lower Thickness

Under the same conductivity, the copper layer is further thinned, compared with the traditional 6μm lithium-electric copper foil thinning by 1%-12%, effectively improving the volume energy density;

Lower Weightiness

Under the same performance requirements, the amount of metal is further reduced, compared with the traditional 6μm lithium-electric copper foil, the weight is reduced by 60%-75%, and the mass energy density is significantly improved;

C-rate

Customized development for different scenarios, and can achieve ultra-thin surface coating, effectively reduce the internal resistance of the battery, can meet the 2-5C rate requirements.

Pinhole

Magnetron sputtering high-efficiency double-sided coating, the coating is more dense, the surface of 0 pinholes, power cycle life significantly improved.

"Scale Armor" Series

*Compared to traditional 12μm aluminum foil

Lower Thickness

High-speed low-temperature magnetron sputtering can achieve further thinning of the base film, compared with the traditional 12μm lithium-ion aluminum foil thinning 30%-45%, greatly improve the volume energy density;

Lower Weightiness

Polymer-based film replaces part of the metal, relative to the traditional 12μm lithium-ion aluminum foil weight reduction of 55%-65%, effectively improve the quality of energy density;

C-rate

Customized development for different scenarios, and can achieve ultra-thin surface coating, effectively reduce the internal resistance of the battery, can meet the 2-4C rate requirements.

Pinhole

Magnetron sputtering high-efficiency double-sided one-time coating, to avoid the impact of splash, the coating is more dense, the surface 0 pinhole 0 particles, power cycle life significantly improved.

Copper&Aluminum Composite Foil

Lower Thickness

Exquisite magnetron sputtering technology regulates the thickness of the coating and realizes the customized development and design of ultra-thin coating.

Durability

For negative lithium, semi-solid, solid-state and other multi-scene needs for technical research and development reserves.